Stainless Steel Screw

Truss Head Stainless Steel Screws are a kind of fasteners that are produced with an extra wide and slightly rounded head. Machine screws like the Pan Head SS 316 Screws have a flat to with the sides of the head being rounded. Frequently characterised as head with a flat top the bottom of Flat Head SS 304 Screws is cone shaped or countersunk.

Most stainless steel screw manufacturers prefer using grades 304 and 316 to produce fasteners partially due to their formability and partially due to their superior ductile properties. However, these two properties are not solely responsible for being selected while producing fasteners. Other parameters include the kind of application it is to be suited for, tensile properties as well as corrosion resistance. Not forgetting the cost factor, which is what makes alloy grade 304 screws a favoured one amongst suppliers and SS Machine Screws Manufacturers alike. You can have a look at the S Screw Size Chart by clicking the link here.

In addition to being a very versatile and popular grade, the 304L SS Dome Head Screws have some levels of corrosion resistance but is majorly used for those applications that are not really demanding of its properties. However, since the grades can be modified to suit the needs of our clients. For instance grade 304 L and SS 316L Button Head Screws are low carbon modified alloys, which are useful for welding operations, as these grades are less prone to sensitization. On the other hand, 304H and 316H SS Flange Head Screws are high carbon variants of the alloys and have been modified for high temperature purposes. Check out the link for SS Screw Price List In India here.

Specification Format of Stainless Steel Screw

| Stainless Steel Screws Standard Specifications | American Society of Mechanical Engineers SA 193 |

| Standard of 316 SS Machine Screws | American Society for Testing and Materials, Deutsches Institut, British Standards |

| SS 304 Screw Length in Inch | 0.11 Inch to 10 Inch |

| Available Size of SS screw | M3 to M56, 12.7MM to 50.8MM and also available in custom size |

Dimensions Standard of SS Screw

| Nominal Size* | Phillips Driver Size | Head Diameter | Head Height

|

Width of Slot | Depth of Slot | Dimension of Recess | |||||||

| Max | Min | Ref | Max | Min | Max | Min | Dia. Max (M) | Dia. Min (M) | Depth Max (G) | Depth Min (G) | Width Min (N) | ||

| 2 | 1 | .172 | .147 | .051 | .031 | .023 | .023 | .015 | .102 | .089 | .063 | .047 | .017 |

| 3 | 1 | .199 | .141 | .059 | .035 | .027 | .027 | .017 | .107 | .094 | .068 | .052 | .018 |

| 4 | 1 | .225 | .195 | .067 | .039 | .031 | .030 | .020 | .128 | .115 | .089 | .073 | .018 |

| 5 | 2 | .252 | .220 | .075 | .043 | .035 | .034 | .022 | .154 | .141 | .086 | .063 | .027 |

| 6 | 2 | .279 | .244 | .083 | .048 | .039 | .038 | .024 | .174 | .161 | .106 | .083 | .029 |

| 7 | 2 | .305 | .268 | .091 | .048 | .039 | .041 | .027 | .189 | .176 | .121 | .098 | .030 |

| 8 | 2 | .332 | .292 | .100 | .054 | .045 | .045 | .029 | .204 | .191 | .136 | .113 | .032 |

| 9 | 2 | .358 | .316 | .108 | .054 | .045 | .049 | .032 | .214 | .201 | .146 | .123 | .033 |

| 10 | 3 | .385 | .340 | .116 | .060 | .050 | .053 | .034 | .258 | .245 | .146 | .123 | .034 |

| 12 | 3 | .438 | .389 | .132 | .067 | .056 | .060 | .039 | .283 | .270 | .171 | .148 | .036 |

| 14 | 3 | .507 | .452 | .153 | .075 | .064 | .070 | .046 | .283 | .270 | .171 | .148 | .036 |

| 16 | 3 | .544 | .485 | .164 | .075 | .064 | .075 | .049 | .303 | .290 | .191 | .168 | .039 |

Torque Chart of 316 Stainless Steel Machine Screws

| SS Screw Sizes in Inches | Threads Per Inch |

Standard Torque in Inch | |||||

| Stainless Steel Screw | SS Screw | ||||||

| 1/4 | 20 | 75.2 | 78.8 | ||||

| 28 | 94.0 | 99.0 | |||||

| 5/16 | 18 | 132 | 138 | ||||

| 24 | 142 | 147 | |||||

| 3/8 | 16 | 236 | 247 | ||||

| 24 | 259 | 271 | |||||

| 7/16 | 14 | 376 | 393 | ||||

| 20 | 400 | 418 | |||||

| 1/2 | 13 | 517 | 542 | ||||

| 20 | 541 | 565 | |||||

| Sizes of 316 SS Machine Screws in Inches |

Threads Per Inch |

Standard Dry Torque in Foot-Pounds | |||||

| SS 304 Screw | Stainless Steel Screw | ||||||

| 1 1/8 | 7 | 413 | 432 | ||||

| 12 | 390 | 408 | |||||

| 1 1/4 | 7 | 523 | 546 | ||||

| 12 | 480 | 504 | |||||

| 1 1/2 | 6 | 888 | 930 | ||||

| 12 | 703 | 732 | |||||

Stainless steel screw types and uses

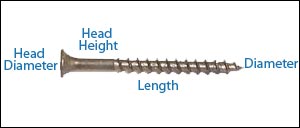

Characterized as having a helical ridge, known as an external thread, a screw is a fastener that is self-threading. The basic functioning of the screw is when it is turned, the threads cut into the material it is to be fastened into by creating a form of an internal thread that pulls the fastened material together in a snug manner such that it prevents pull out. This being said, there are many kinds of screws.

Thread rolling screws - Used in those applications that cannot tolerate the formation of loose chips by a thread cutting operation.

Security head screw - As the name suggests, these screws are seen where theft or vandalism are frequent occurrences. Impossible to request the head of the screw, or if required the head of the screw could be removed by severing it after installing the screw.

Wood screw - Intended to join two pieces of wood together, the heads of these screws are available in the form of a pan, flat, or oval-heads.

Twinfast screw - Owing to the fact that these screws have 2 threads, they can be driven almost 2 times faster in comparison to a regular screw with the same pitch.

Sheet metal screw - These screws have a sharp thread, which can cut through plastic, sheet metal as well as wood. Considered to be excellent if metal hardware is to be attached to wood. Since the shank of these screws is fully threaded, they offer good retention in wood.

Mirror screw - Typically used to mount a mirror, these flat head wood screw has a screw in chrome plated cover.

Lag screw - Occasionally referred to as lag bolts, they are known to have high toughness properties, which finds use in applications where these sturdy screws can be used to connect heavy lumber or other heavy materials that have to bear an intense load.

Eye screw - These loop head screws are also known as vine eye or screw eye due to their appearance. These stainless steel screw eyes find use in applications involving wire lines across the surface of buildings.

Drywall screw - Considered to be the most versatile of all screws, they are intended to be used to attach drywall to wood or metal studs.

Hammer drive screw - The main purpose of these screws is that they aid in attaching a manufacturers data plates to the relevant equipment.

Double ended screw - Similar to wood screws and also known as a dowel screw or a hanger bolt, these screws have two pointed heads minus the head. Thus, a double ended screw could be used to make a hidden joint between two pieces of wood.

Deck screw - Typically supplied in a larger gauge, they tend to be similar to drywall ones, with the exception of its improved resistance to corrosion.

Masonry screw - These screws can be referred to as concrete screw or Tapcons or Confast screw. Used to fasten metal, wood, or other materials to concrete or masonry, they are blue in colour and could be produced with or without a corrosion coating.

Chipboard screw - They are also known as particleboard screws. While these screws may be similar to a drywall screw, the difference that a chipboard screw has a thinner shank, which in turn has the ability to provide better resistance to pull-out in particleboard.